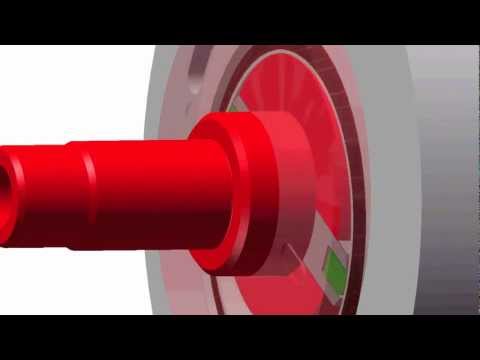

Eccentric Cam

- Feature – the eccentric cam controls the rotating gate’s position and maintains a near-zero constant distance between the distal end of the rotating gate and the stator bore, which allows the compressor to scale across large capacity and speed ranges.

- Benefit – the eccentric cam reduces friction and wear by preventing sliding contact between the gate and the housing bore. What would be sliding contact between the tip of the gate and housing bore is replaced by rolling contact between the gate and eccentric cam, resulting in very low friction and wear. As a result, sliding friction is removed from the fluid chamber, thereby reducing fluid heating to further improve the compressor’s efficiency.

- Feature – the rotating vane is controlled by the eccentric cam and prevents the vane from contacting the housing bore. As a result, the size and weight of the rotating vane has extremely low impact on kinematic and friction losses.

- Benefit – the vane can be constructed with a robust cross section that allows the spool compressor to easily handle high compression ratios and absolute pressure differentials while easily scaling to larger capacity applications.

- Feature – the tip seal is pressure activated and placed in the slots at the end of the rotating vane, isolating the suction and compression chambers. The seal, constructed of a light-weight, low friction plastic alloy, covers a very small gap and experiences very low force.

- Benefit – tip seals generate ultra-low friction with limited wear and outstanding reliability.

- Features – spool endplates are attached to the spool hub to form the rotating spool assembly. These endplates enable various means for sealing the fluid chambers between the endplates and the compressor housing.

- Benefit – sealing is achieved through pressure activated seals, labyrinth seals or close-tolerance geometry. Multiple sealing options make the spool compressor adaptable across a broad range of operating conditions, capacities and a wide range of refrigerants. Because the endplates rotate with the vane with minimal radial relative movement, sliding friction between the vane and the endplate is virtually eliminated, significantly reducing friction.

- Features – the compressor’s geometry provides easy access to the compression process and intermediate pressures.

- Benefit– the implementation of advanced compression techniques, such as vapor injection, oil injection, and economizing, can easily be achieved at minimal cost.

- Features – the spool compressor’s volumetric and overall efficiency is relatively constant across a broad speed range.

- Benefit – variable speed operation is an excellent solution for variable capacity applications.