What makes the Spool Compressor so unique?

Simple Design, High Capacity Density, and Low Cost. TORAD’s revolutionary Spool Compressor represents a significant breakthrough in compressor simplicity, capacity density and manufacturing cost. With only four key components that are easily manufactured on cost-effective machine tools, the spool compressor is positioned to dramatically change the air conditioning and refrigeration compressor marketplace by delivering significant cost savings to OEMs. The spool compressor’s unique design enables it to scale and be easily configured across a broad range of compression applications. Compared to most legacy compressor technologies, the spool compressor is smaller in size, lower in weight, and easier to manufacture, yielding a significantly lower overall cost. The TORAD Spool Compressor is the next level of compressor technology innovation.

Simple Design, High Capacity Density, and Low Cost. TORAD’s revolutionary Spool Compressor represents a significant breakthrough in compressor simplicity, capacity density and manufacturing cost. With only four key components that are easily manufactured on cost-effective machine tools, the spool compressor is positioned to dramatically change the air conditioning and refrigeration compressor marketplace by delivering significant cost savings to OEMs. The spool compressor’s unique design enables it to scale and be easily configured across a broad range of compression applications. Compared to most legacy compressor technologies, the spool compressor is smaller in size, lower in weight, and easier to manufacture, yielding a significantly lower overall cost. The TORAD Spool Compressor is the next level of compressor technology innovation.

Is the Spool Compressor less expensive to produce than other compressors of similar capacity?

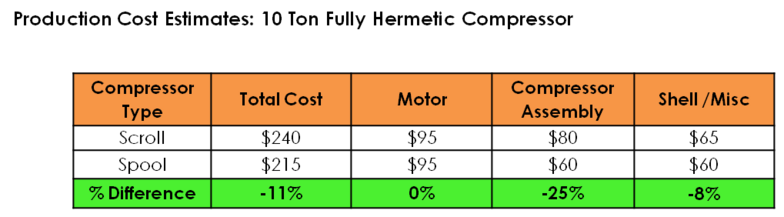

Yes. The Spool Compressor’s simple design, low part count, and high displacement density enable significant reductions in capital expenditures and production costs. The attractive cost reductions delivered by the Spool Compressor are illustrated in the table below displaying a cost comparison between a 10 Ton Scroll and a 10 Ton Spool compressor.

Yes. The Spool Compressor’s simple design, low part count, and high displacement density enable significant reductions in capital expenditures and production costs. The attractive cost reductions delivered by the Spool Compressor are illustrated in the table below displaying a cost comparison between a 10 Ton Scroll and a 10 Ton Spool compressor.

Is the Spool Compressor’s design more streamlined than other compressors?

Yes. Many of the compression technologies employed today feature complex geometries that are difficult to design and even more of a challenge to manufacture. The TORAD Spool Compressor’s simple design can be produced using inexpensive machine tools and techniques, leading to significant cost savings.

Yes. Many of the compression technologies employed today feature complex geometries that are difficult to design and even more of a challenge to manufacture. The TORAD Spool Compressor’s simple design can be produced using inexpensive machine tools and techniques, leading to significant cost savings.

Is the Spool Compressor’s footprint smaller than legacy compressors of similar capacity?

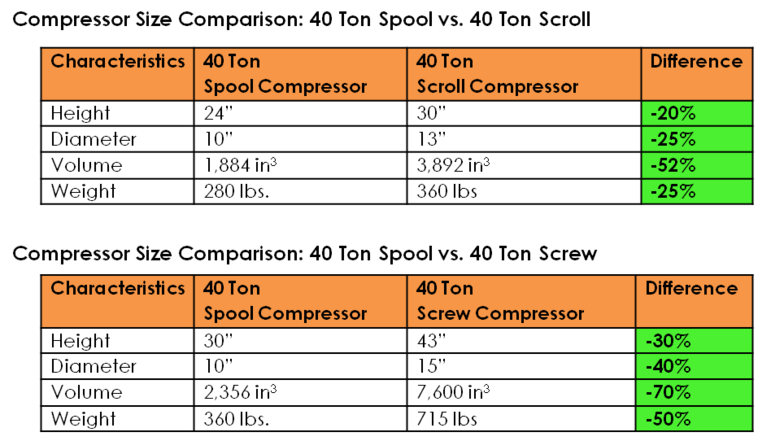

Yes. The Spool Compressor’s high displacement density allows it to be delivered in a form factor that can be as much as 40% smaller than legacy compressors of similar capacity. The comparisons illustrated in the tables below highlight the significant size advantages of the TORAD Spool compressor.

How many key components are included in the Spool Compressor?

Only 4. The Spool Compressor’s simple design includes only four key components that are easily manufactured on cost-effective machines. The compressor’s minimal part count simplifies the manufacturing process and minimizes supply chain complexities to reduce overall processing costs.

Only 4. The Spool Compressor’s simple design includes only four key components that are easily manufactured on cost-effective machines. The compressor’s minimal part count simplifies the manufacturing process and minimizes supply chain complexities to reduce overall processing costs.

Can the Spool Compressor be used across a broad capacity range?

Yes. The Spool Compressor does not have any inherent size limitations related to the function of the mechanism. Currently, the spool compressor is being designed for use across a broad capacity range. It is expected the spool compressor will be economically viable up to 300 hp.

Yes. The Spool Compressor does not have any inherent size limitations related to the function of the mechanism. Currently, the spool compressor is being designed for use across a broad capacity range. It is expected the spool compressor will be economically viable up to 300 hp.

Can the Spool Compressor be used in variable speed capacity applications?

Yes. The spool compressor is unique in that it applies positive sealing to close the compressor chamber – much like a piston compressor but functions in a rotary manner. This enables the Spool Compressor’s volumetric and overall efficiency to remain relatively constant across a broad operating range. Efficiency across this range is achieved without modifications to the compressor or added cost, making it an excellent solution for variable capacity applications.

Yes. The spool compressor is unique in that it applies positive sealing to close the compressor chamber – much like a piston compressor but functions in a rotary manner. This enables the Spool Compressor’s volumetric and overall efficiency to remain relatively constant across a broad operating range. Efficiency across this range is achieved without modifications to the compressor or added cost, making it an excellent solution for variable capacity applications.

Can advances compression techniques be deployed on the Spool Compressor?

Yes. The cleaner design of the Spool Compressor provides easy access to the intermediate pressure chambers to enable the implementation of advanced compression techniques – such as vapor injection, oil injection, and liquid injection – all of which can easily be achieved at a minimal cost.

Yes. The cleaner design of the Spool Compressor provides easy access to the intermediate pressure chambers to enable the implementation of advanced compression techniques – such as vapor injection, oil injection, and liquid injection – all of which can easily be achieved at a minimal cost.

What are the types of seals that are used in the spool compressor?

Tips Seals and Housing Seals. One of the main features that makes the Spool Compressor so unique is that it is a rotary machine that also uses active sealing elements. The compressor uses two types of seals: tip seals and housing seals. The tip seals are placed in slots at ends of the vane. They are pressure activated providing a compliant seal between the suction and compression chambers. Because the tip seal spans such a small gap between the vane and the housing bore, it experiences extremely low forces. As a result, the tip seal can be constructed of a low friction, wear-resistant plastic alloy. The second type of seal, the housing seal, provides sealing between the rotating spool assembly and the compressor housing. Multiple sealing options make the Spool Compressor effective across a broad range of operating conditions, capacities and refrigerants.

Tips Seals and Housing Seals. One of the main features that makes the Spool Compressor so unique is that it is a rotary machine that also uses active sealing elements. The compressor uses two types of seals: tip seals and housing seals. The tip seals are placed in slots at ends of the vane. They are pressure activated providing a compliant seal between the suction and compression chambers. Because the tip seal spans such a small gap between the vane and the housing bore, it experiences extremely low forces. As a result, the tip seal can be constructed of a low friction, wear-resistant plastic alloy. The second type of seal, the housing seal, provides sealing between the rotating spool assembly and the compressor housing. Multiple sealing options make the Spool Compressor effective across a broad range of operating conditions, capacities and refrigerants.

Which refrigerants can be used in the Spool Compressor?

The spool compressors have been tested using R134a and R410a refrigerants and can be easily modified for any of the available HFC or HCFC-based refrigerants. The Spool Compressor has not yet been tested with natural refrigerants, but there are currently no known design limitations that would prevent the use of these refrigerants.

The spool compressors have been tested using R134a and R410a refrigerants and can be easily modified for any of the available HFC or HCFC-based refrigerants. The Spool Compressor has not yet been tested with natural refrigerants, but there are currently no known design limitations that would prevent the use of these refrigerants.

Can the Spool Compressor be applied in refrigeration applications?

Yes. The spool compressor is a positively sealed device that performs well on low evaporator pressures experienced in refrigeration applications. The spool compressor also has no internal volume ratio. As a result, it will not suffer from the under-compression problems experienced by scroll compressors when applied in low temperature applications.

Yes. The spool compressor is a positively sealed device that performs well on low evaporator pressures experienced in refrigeration applications. The spool compressor also has no internal volume ratio. As a result, it will not suffer from the under-compression problems experienced by scroll compressors when applied in low temperature applications.

In what types of configurations can the spool compressor be designed?

Open, semi and fully hermetic. The spool compressor can be configured in an open drive, semi-hermetic or fully hermetic configuration and can be used in vertical and horizontal orientations.

Open, semi and fully hermetic. The spool compressor can be configured in an open drive, semi-hermetic or fully hermetic configuration and can be used in vertical and horizontal orientations.

What are the pressure limits of the Spool Compressor?

Like all compressors, the spool compressor must be designed to handle the pressure that it will be subject to in operating conditions. This is a function of the refrigeration and the system design that the spool compressor will be used in. The spool compressor currently operates under normal air conditioning settings using refrigerants R134a as well as R410a.

Like all compressors, the spool compressor must be designed to handle the pressure that it will be subject to in operating conditions. This is a function of the refrigeration and the system design that the spool compressor will be used in. The spool compressor currently operates under normal air conditioning settings using refrigerants R134a as well as R410a.

How can compressor OEMs license TORAD’s Spool Technology?

Contact Us. TORAD is currently negotiating license agreements with several OEMs. Please contact us to discuss how you can use TORAD spool technology to dramatically reduce processing costs and improve profit margins.

Contact Us. TORAD is currently negotiating license agreements with several OEMs. Please contact us to discuss how you can use TORAD spool technology to dramatically reduce processing costs and improve profit margins.

Is TORAD a privately held company?

TORAD is a privately held company located in Alpharetta, Georgia.

TORAD is a privately held company located in Alpharetta, Georgia.

Is the TORAD Spool Compressor technology patented?

TORAD has multiple U.S. patents and several patents pending in the U.S. and around the world.

TORAD has multiple U.S. patents and several patents pending in the U.S. and around the world.